You’ve heard the saying ‘the dose makes the poison’, and it’s true – the concentration of a toxic substance makes the difference between being at or below the ‘no observable effect concentration/level (NOEC or NOEL) and death. But concentration isn’t the only factor when you’re looking at certain hazardous materials.

Respirable crystalline silica (RCS), which is listed by the International Agency for Research on Cancer (IARC) as a Group 1 Carcinogen, is a known industrial and occupational hazard. But why? Crystalline silica (of which the most common form is quartz, the second most common terrestrial mineral) is all around us, in playground sand and rocks, and as an integral part of concrete and mortar. Yet we don’t see people dropping dead from silicosis every few meters, and most people have only been injured by quartz if they dropped a big rock on their foot or got sand in their eye at the beach.

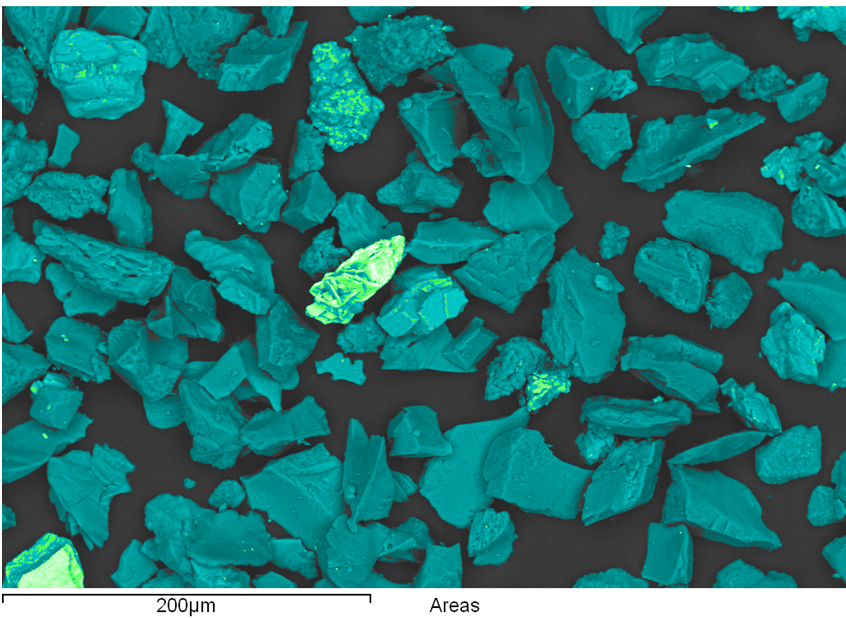

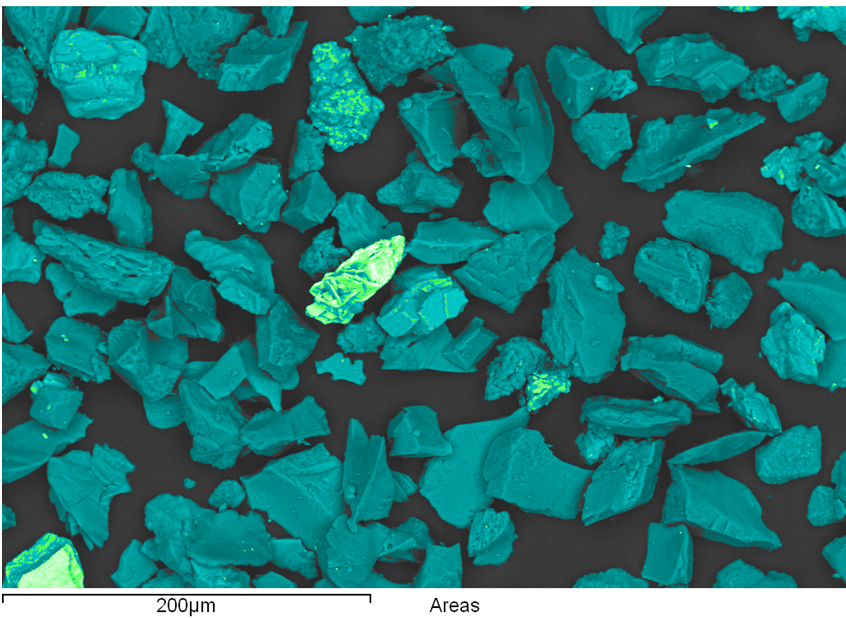

That brings us to size. Quartz (and cristobalite and tridymite, the other two primary polymorphs of crystalline silica) is hazardous if it’s small enough to get deep into your lungs and get trapped. Silicosis is a devastating lung disease, which can take years to develop, caused by fine silica particles embedding themselves in the alveolar sacs and ducts where oxygen and carbon dioxide gases are exchanged. When our lung’s cleaning macrophages try to dispose of the nuisance dust, the toxicity of the crystalline silica causes an immune response that releases a bunch of nasty stuff, and this results in characteristic fibrous nodules and scarring (plaques) in the lungs.

So – how small is small enough to cause lung damage? The usual nomenclature for airborne or potentially airborne particulate size is the Particulate Matter (PMx) parameter. The PMx values of interest are the ‘respirables’ PM2.5 and PM4 (2.5 is used in the USA and 4 is used in Australia – this size gets all the way down into your lungs), PM10 (Thoracic – it’ll get caught deep in your throat or in the top of your lungs and will probably be coughed out in mucous), and PM100 (inhalable – will just stick in your mouth or the top of your throat and will likely be coughed or spat out, or swallowed). The value after PM is referred to as the ‘Equivalent Aerodynamic Diameter’ or EAD and shouldn’t be confused with physical diameters. |