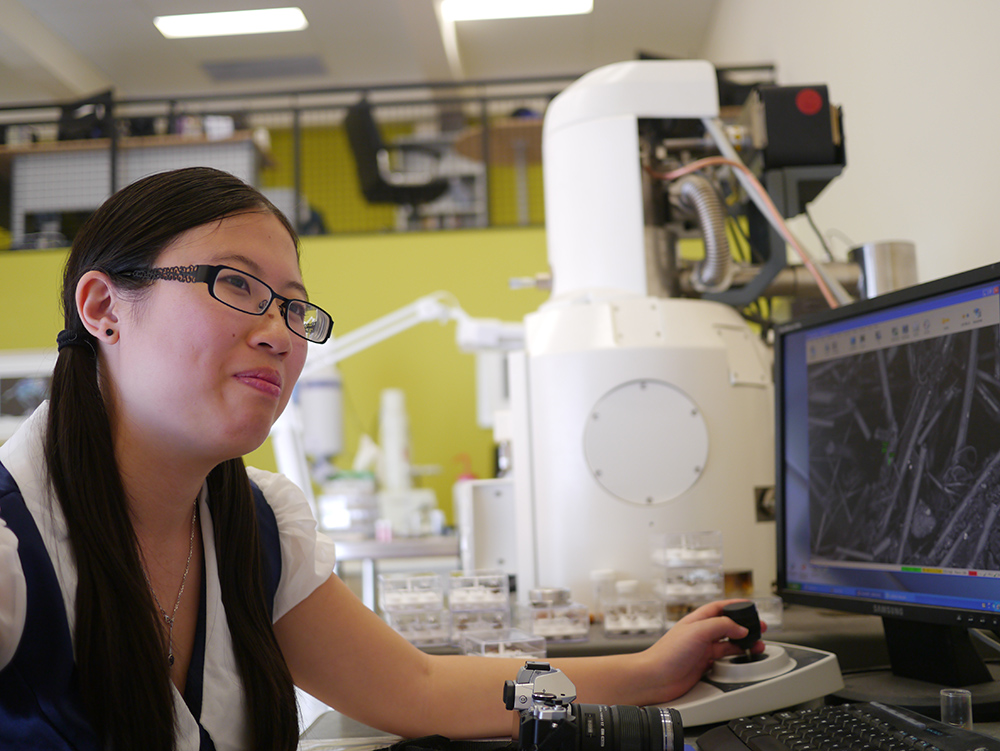

A scanning electron microscope (SEM) produces images of a sample by scanning over it with a high energy beam of electrons which can be focused to a spot approximately 1 nanometer in diameter, allowing resolution limits down to about 10 nm. Here at Microanalysis we run two scanning electron microscopes, the JEOL 5800 LV and the Carl Zeiss EVO 50. Our SEMs offer non-destructive, high resolution imaging via either secondary electron detection (emphasising topographical features) or via backscatter electron detection (emphasising compositional variation) as well as compositional analysis via energy dispersive spectroscopy (EDS) which can provide fast chemical (elemental) analysis of the field-of-view or point-by-point to a spatial resolution of ~4 µm. We can also perform X-ray mapping, which can determine spatial location of every element on the periodic table from Be onwards, and phase-mapping, which allows us to look at the correlation between the elements and build ternary diagrams to give information about compounds and the relationships between elements that are present.

Additionally, we have the capability for in-depth, automated particle sizing and compositional analysis via our ‘Feature’ and INCA Mineral software. These fully automated image recognition software packages collect images of up to 10,000 particles on a filter membrane (or other suitably flat collection surface) for size distribution and composition analysis.

The comparison of elemental ratios together with mineralogical information allows for mineral categorization according to set criteria on collected data. This allows us to report sizes by composition information.

INCA Mineral allows individual grains to be completely characterised by mineralogy and liberation analysis allows for interpretation and reporting of each phases’ proximity within the grain.